Radiant HeatĮvery wonder how an attic can get up to 140✯ when it’s only 95✯ outside? How about the huge temperature difference in the shade versus in the sun? Radiant heat is the answer. Allow air space or place insulation like rigid foam between building elements to prevent thermal bridging and stop the flow of conductive heat.

#Heat transfer how to#

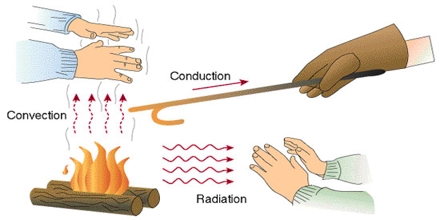

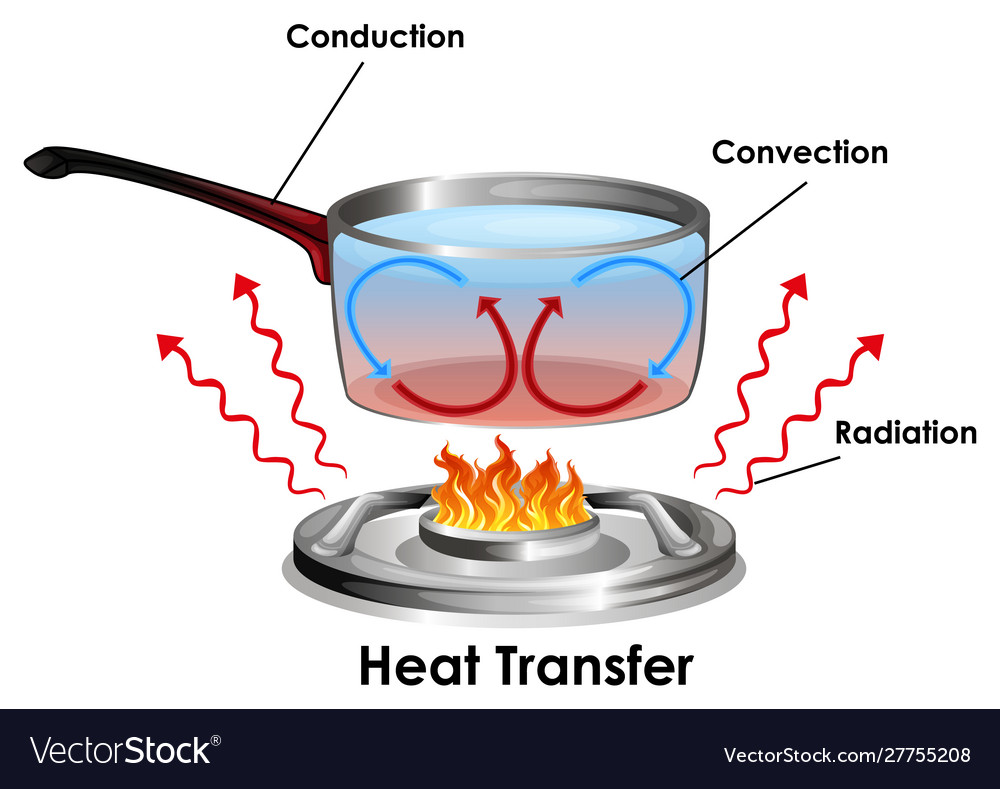

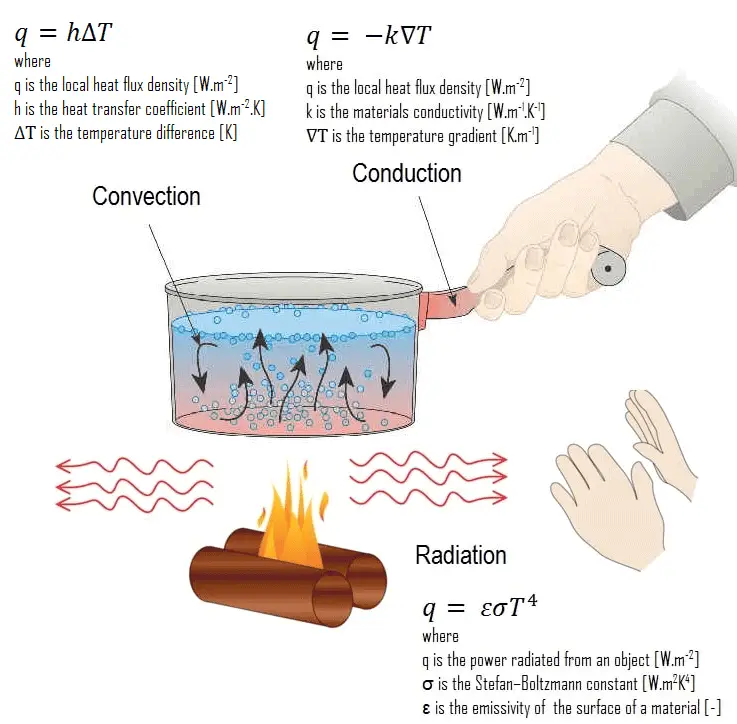

How to Stop Conductive Heat: Use a thermal break where possible. Just like electricity is conducted along electric lines, conductive heat is transferred much the same way. The heat flows into the cooler item until a temperature equilibrium is reached. The heat transfers directly from the stove top to the pot, and again from the pot to the water causing the water to boil.Ĭonductive heat transfer occurs when a cooler item comes into contact with a warmer item. An example of conductive heat would be putting a pot of water on the stove and turning the stove on high. When it comes to insulating buildings, conductive heat has very little effect. Let’s look at each type of heat transfer and how to make it work for you, not against you. In the winter we fight to keep the heat in, and in the summer we strive to keep it out. Heat is always trying to move toward cooler areas. All three of these should be addressed if you want an effective insulation design for your old home. There are three types of heat transfer: conduction, convection, and radiation. Whether you are in a hot climate or cold climate, it’s all about keeping heat in its place. As a global leader in custom-designed water treatment programs, Chem-Aqua has the experience, knowledge, and technology to keep your facility running efficiently.Understanding the three types of heat transfer will help you insulate smarter and not just throw money at expensive energy bills like most people. They require expertise and management to control scale, deposits, corrosion, unwanted microbiological activity, water usage, and environmental impact. For example, the average occupant in an office setting may generate up to 400 BTU/hour of heat while doing general office work.īoilers, cooling towers, and chillers are industry work horses for transferring heat from one location to another. Radiation is the least efficient method of heat transfer.įacility engineers must take into account all three forms of heat transfer: conduction through a heat exchanger metal, convection of heat through fluids such as water and air, and radiant heat from equipment and occupants. For example, we feel heat from a heated pot and flame even though we are not touching them. Radiation is a method of heat transfer that does not rely upon any contact between the heat source and the heated object. A steam boiler functions in much the same way.

For example, as water is heated in a pot, the less dense hotter water rises to the top of the pot while the more dense cool water sinks to the bottom, setting up a natural circulation.

Convection happens when there is a difference in temperature between two parts of a liquid or gas. The same concept applies to insulators.Ĭonvection is the transfer of heat within a liquid or gas fluid, due to mixing of hotter materials rising and cooler materials sinking. As a general rule of thumb, materials that conduct heat well, conduct electricity well too. Materials like glass, wood, and air are poor conductors of heat and are known as insulators. Metals are usually good conductors of heat, but not every material is. Over time, heat from the fire will migrate up through the metal handle and eventually become too hot to hold. An example of heat transfer through conduction is a metal handle on a heated pot. Conduction is the transfer of heat through physical contact. Heat always flows from higher temperature to lower temperature in one of three ways: conduction, convection, and radiation.Ĭonduction is one of the most common forms of heat transfer. Failure to transfer heat effectively to and from your equipment and processes may lead to increased operating costs, downtime, unscheduled maintenance, and reduced equipment life.

Transferring heat into a process or rejecting excess heat from your facility is critical to keeping your facility up and running.

0 kommentar(er)

0 kommentar(er)